The Next Generation in Seedbed Finishing

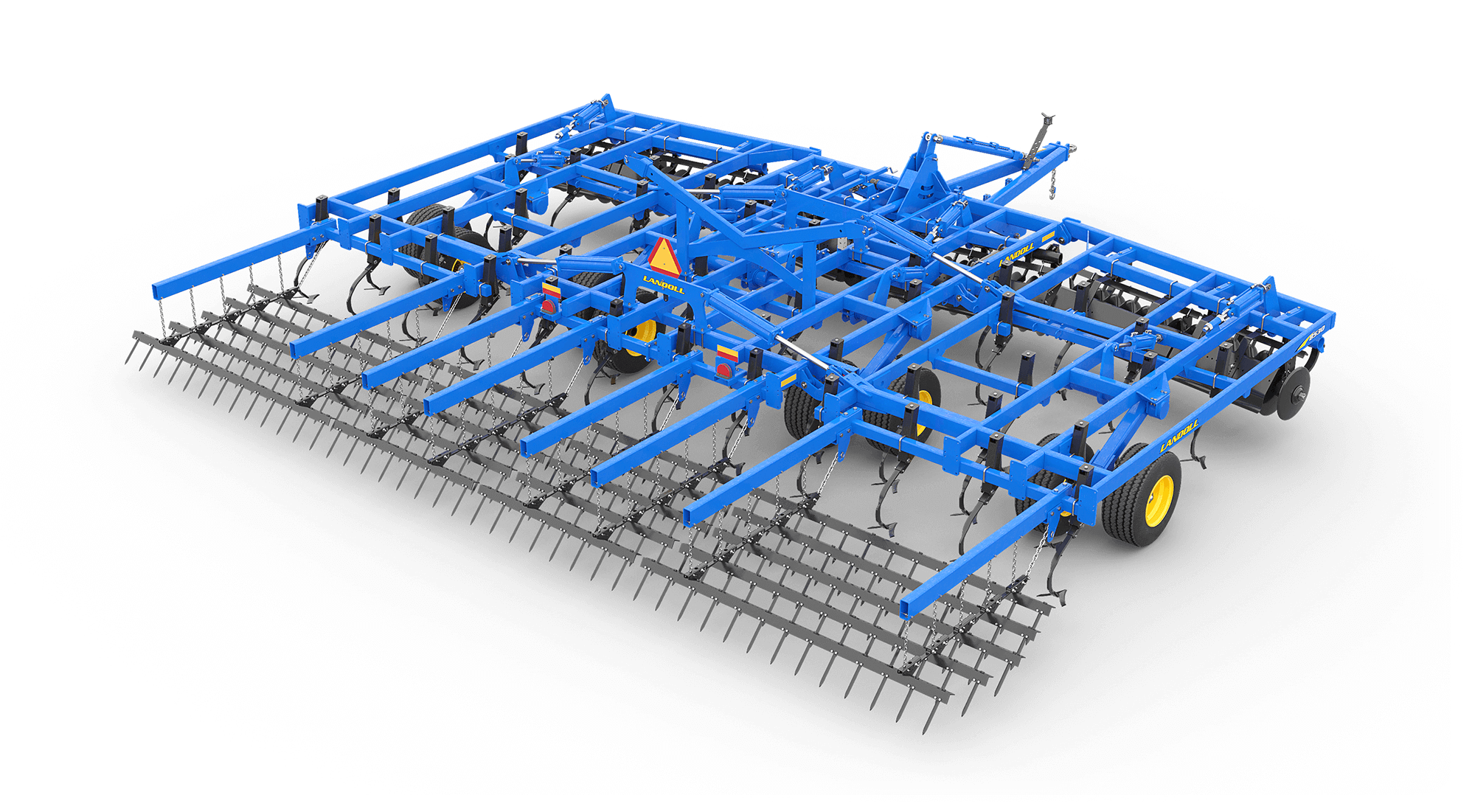

The 8500 Series Finisholl is a one-pass combination secondary tillage tool featuring hydraulically adjusted disc gangs upfront, two-piece s-tine shanks or spring clamp shanks in the middle and a variety of finishing attachment options for the rear.

Creating the Perfect Seedbed

Preparing the perfect seedbed is the key to improving your field’s chances of increasing yields. A firm, level seedbed allows for better seed to soil contact, which results in faster germination and uniform emergence. Proper seedbed preparation helps warm up the soil for earlier planting and a longer growing season. For maximum efficiency and versatility, the 8500 is engineered to pull easy, maintain a uniform working depth, and allow for smooth and even residue flow in the toughest of field conditions.

The Landoll Way

Landoll’s solid reputation for building quality tillage equipment is built into every 8500 Series Finisholl. Precision, laser cut frame components embrace the technology of robotic welding to its fullest. These advanced manufacturing capabilities along with features for unmatched residue clearance and leveling offer the very best in seedbed finishing.

Features for Increasing Yields & Profits

The 8500 Finisholl hydraulically folds for narrow transport widths and manageable transport heights and provides outstanding out-of-ground clearance. Moving from field to field is made easy! The self-leveling hitch maintains the adjusted front-to-rear frame setting at any operating depth and directs positive weight onto the tractor drawbar regardless of the finishing attachment that is chosen. The user-friendly single point depth control simplifies setting the operating depth and provides precise depth control for the ultimate in finish operations.

Upfront, 22” smooth ultra-low concavity disc blades are spaced at 7 ½” with an 8-degree gang angle. The smooth cutting edge of this blade has proven to wear sharper and penetrate better than fluted or wavy blades. In wet, sticky conditions, the smooth surface sheds residue better.

A “split the middle” shank pattern is used for shank placement allowing for 8” spacing with 9” sweeps. Two styles of shanks are offered: s-tine shanks or spring clamp shanks. The two-piece s-tine shanks are geared for rock-free soils, feature 190 lb. point load and will accommodate any sweep with a 47-degree stem angle. The spring clamp shanks feature 190 lb. point load, 10” trip height, and a three-year warranty.

A variety of finishing attachments are available including the 5-row spike, 4-row coil tine, double spike & double reel, 3-row tine and reel, and 3-bar spike and reel.

Features

- Laser Cut, Robotically Welded Frame

- Self-Leveling Hitch

- Single-Point Depth Control

- 7 ½ Degree Wing Flex Up and Down

- Rock Flex Disc Bearing Standards

- Hydraulic Gang Depth Adjustment

- 22” Low Concavity Disc Blades Spaced at 7 ½”

- 8 Degree Gang Angle

- “Split the Middle” Shank Placement – 8” Spacing

- Spring Clamp Shanks with 190 lbs. Point Load

- Two-Piece S-Tine Shanks with 190 lbs. Point Load

- 25 ½” of Under Frame Clearance

- Heavy-Duty Tires and Wheels with Maintenance-Free Lift Axle

- Four Styles of Finishing Attachments Available

- Folds for Narrow Transport Widths

- Blue Powder Coat Paint

- Safety Warning Lights